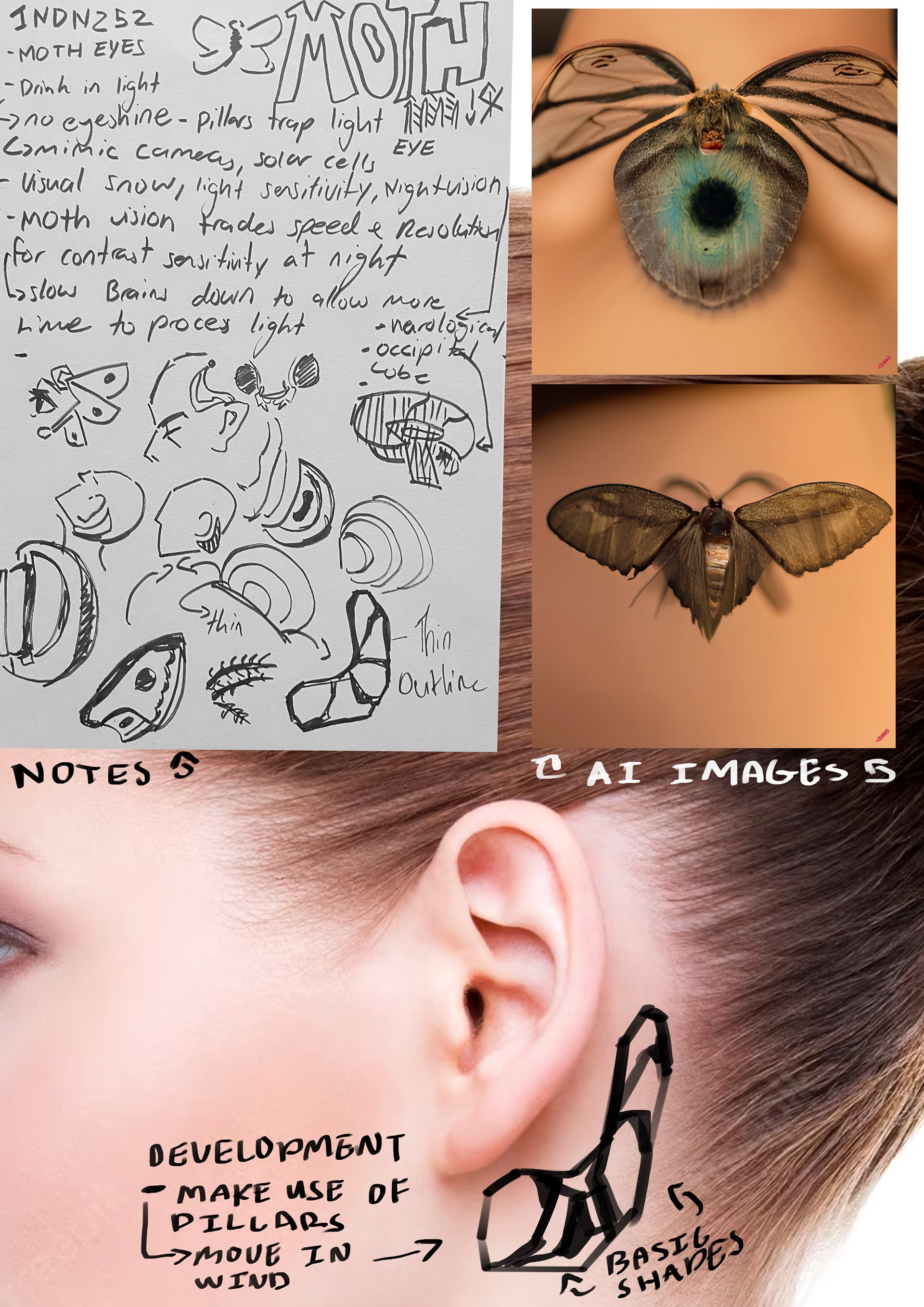

Concepts / Ideation.

My initial Idea was to create a small device that helps the user see in low light. Based off of my personal experience with ‘Visual Snow’ which is a condition which causes individuals to see persistent flickering across their sight. This is most commonly seen as static and can vary from each person in terms of severity.

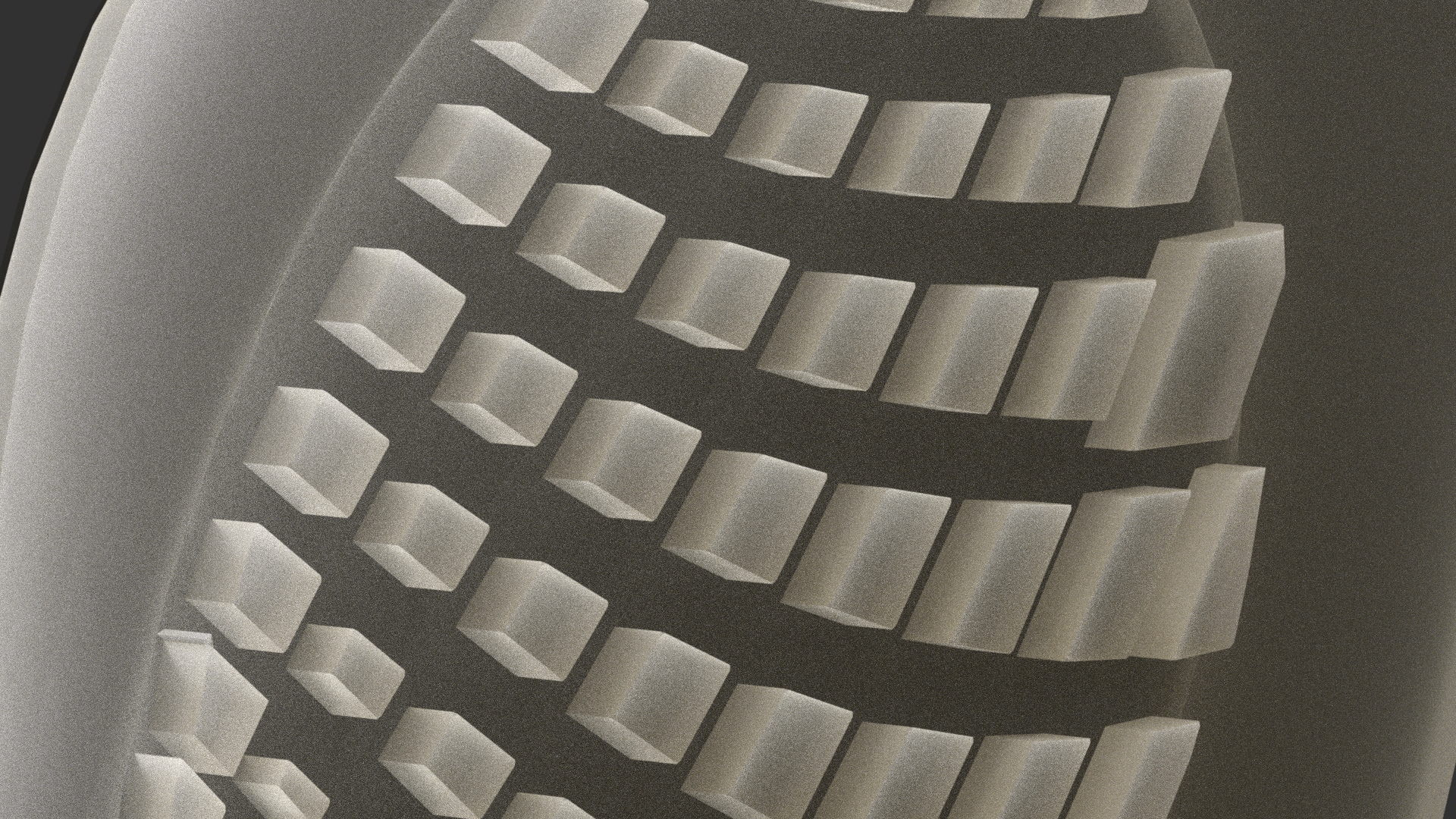

Individuals with visual snow find low-light situations particularly effected. Because of this I took inspiration from moths eyes which make use of tiny pillars to trap light and allow them to see well in the dark.

These ‘pillars’ became the main motif across my designs, acting as my ‘technological’

solution to my aforementioned problem.

solution to my aforementioned problem.

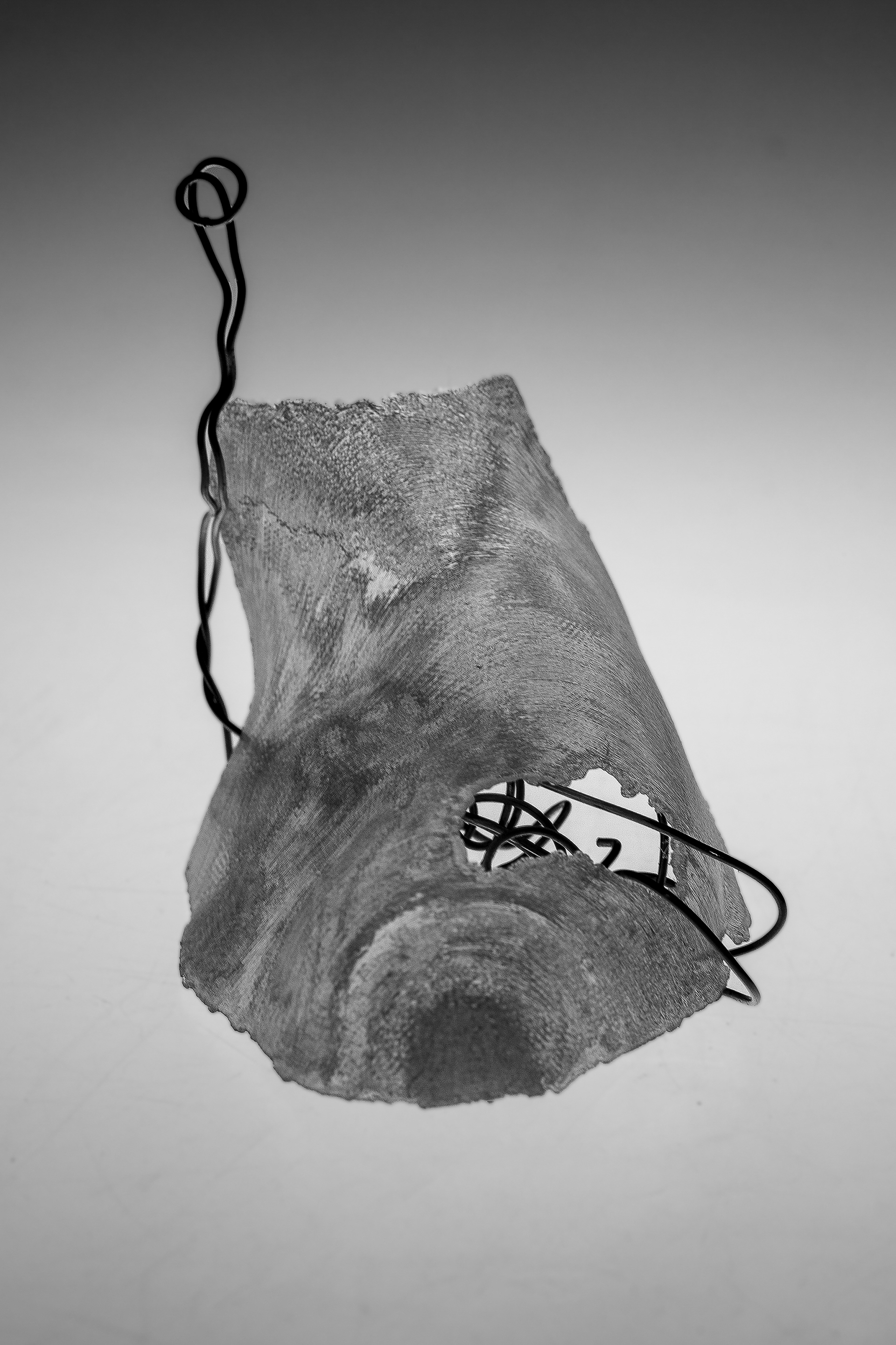

3D Scanning / Cleanup

My 3D scan for my first project was rushed, because of this the scan itself was quite hard to work with and model, resulting in an unsatisfactory print.

I took my time scanning for project two because I wanted to make sure I had a clean surface to model with and as few complications as possible after learning from that initial scan and subsequent print.

Due to my model only making use of a small area behind my ear I cut a lot out of my scan to save space within my file as well as get a better sense of detail when modelling my product. By smoothing and deleting most of the mesh I was able to achieve a clean surface.

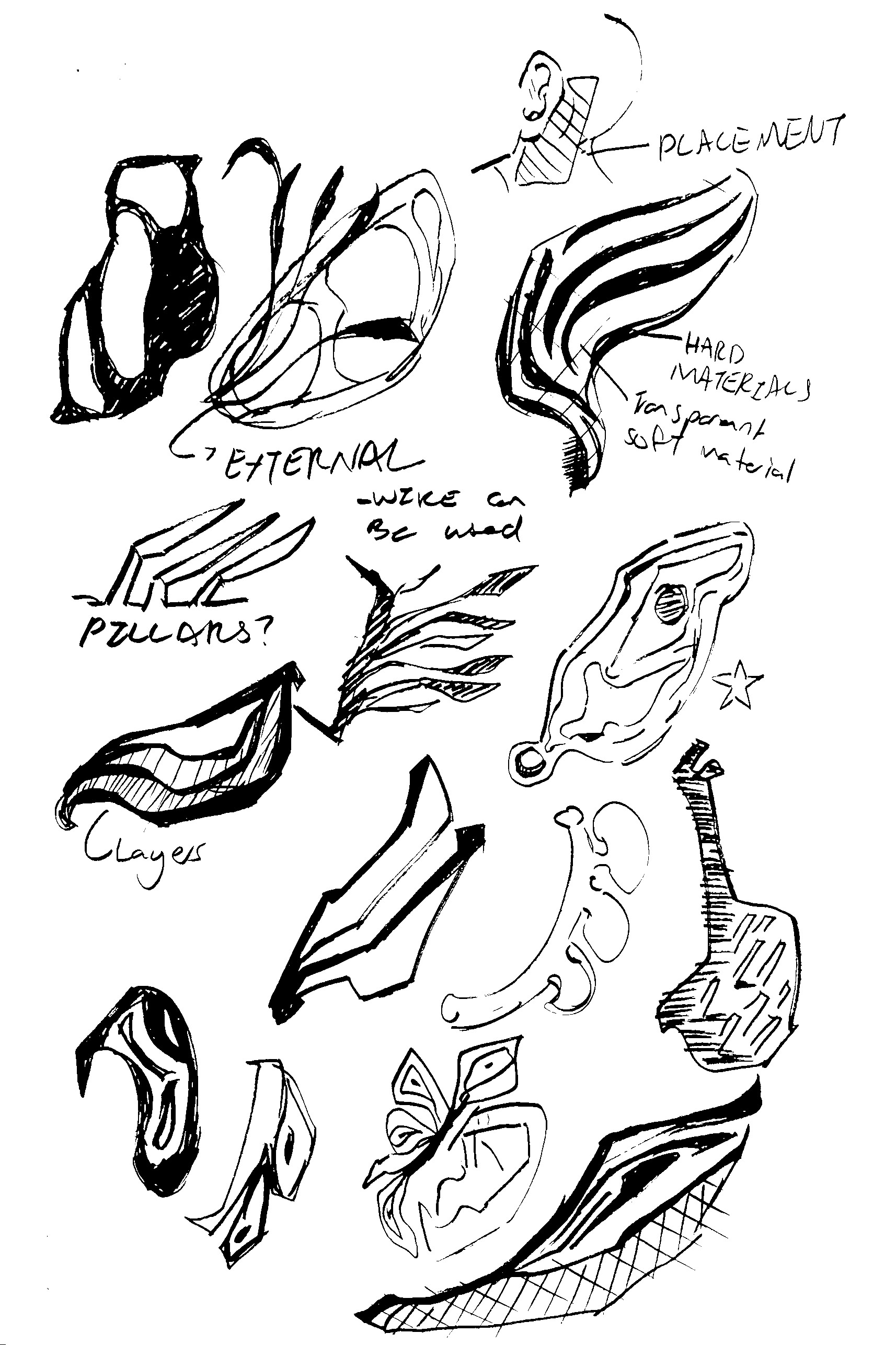

3D Modeling

I was able to model my product using sketches from my concept and ideation page. Inspired by a moth's wing, I wanted the design to be sleek and contemporary, while remaining minimalist and utilitarian. The colours within the design were centered around the black body, which would absorb light.

Print Process

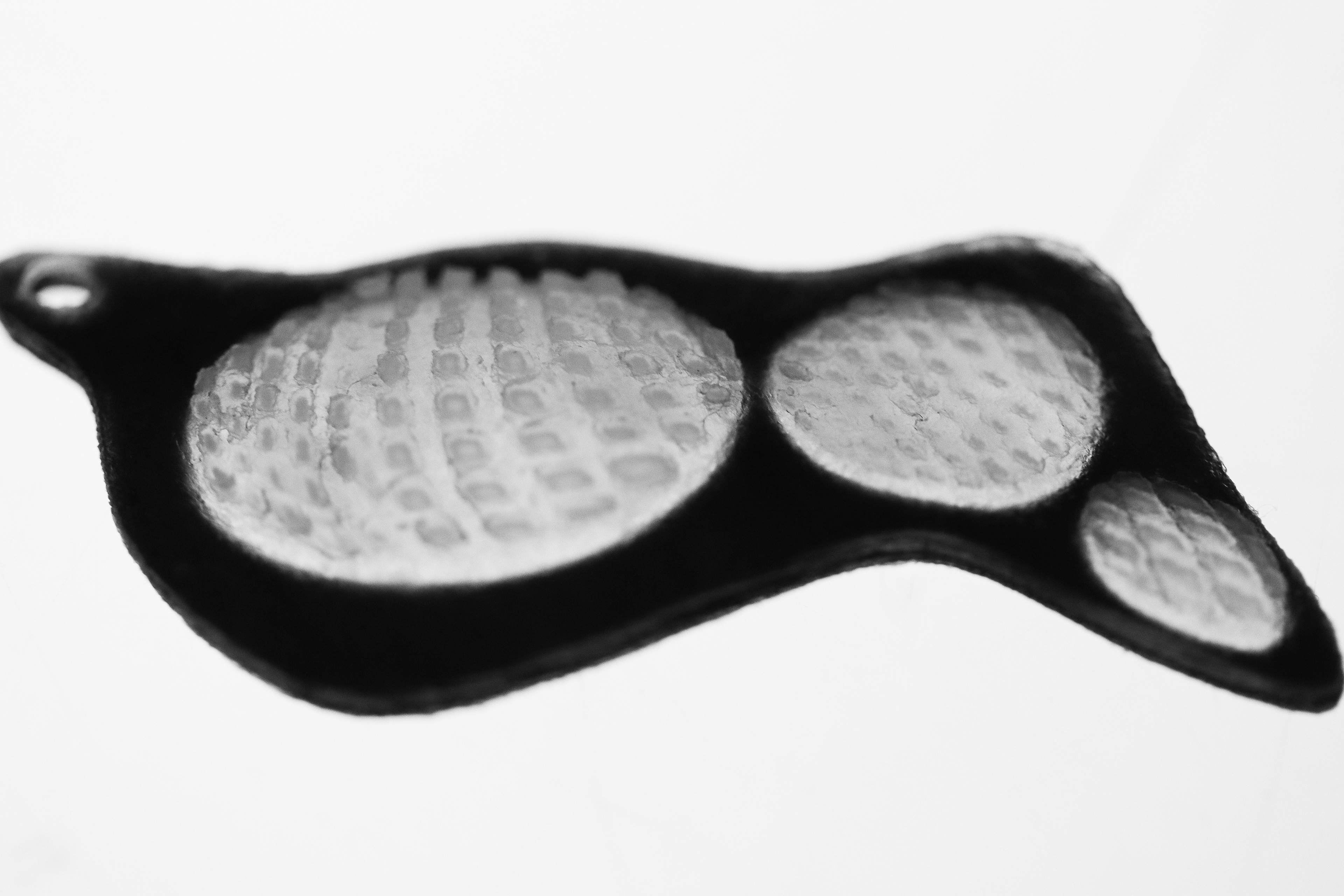

My test prints varied quite widely due to details such as size and material. A and B were PLA to test size, A was too small wile B was too big, I continued on the bigger side with C but ultimately decided I needed to scale down. This resulted in the E being far to small and the agilus pillars did not stick to print. I then printed two more, 5mm bigger than E and embedded the pillars as to prevent them falling off in the cleaning process.

Final Print

The final print learnt from its predecessors, the size fits to my neck like the 3D model and the notches stayed in-tact during (careful) cleaning. I think that while small and facing a few hurdles that my ‘device’ makes use of elements from nature to solve a small problem, visual snow. I’m happy with the final product in terms of not having much experience with 3D modelling and scanning, but I know with better skills and a longer timeframe I could improve on the design.

'ISO'

I wanted the video to reflect the simplicity of the issue I was attempting to design for, visual snow’s static is easy to communicate through video and I wanted to capitalize on that, showing how my device would theoretically work. I’ve named the device ‘ISO’ in relation to the static look the wrong iso can cause on a camera.

Niamh West

300600453